Titanium metallurgy

Titanium alloys exhibit attractive mechanical properties but they are expensive. It summarizes the past, reviews the present and discusses the future of the science and technology of Ti PM while providing the world titanium community with a unique and Titanium Powder Metallurgy: A Review – Part 1 F. Successful production of titanium products, using powder metallurgy (PM) techniques, are more economical and less time intensive than the current production techniques. Metallurgy, the study of metals, is critical to understanding the materials we work with and recommend, cohesive with the overall mission of Fort Wayne Metals. China. Also disclosed is a method of making the titanium alloy by powder metallurgy, and products made from such alloys or billets that may be cast, forged, or extruded. It gives a comprehensive overview on the technical and scientific status in the field of powder metallurgy of titanium and titanium alloys and points out the most important current research topics in this emerging area. The quality of our titanium powder is highly rated by users worldwide. Titanium Powder Metallurgy contains the most comprehensive and authoritative information for, and understanding of, all key issues of titanium powder metallurgy (Ti PM). PRINCIPLES OF EXTRACTIVE METALLURGY RAKES H KUMAR Email : rakesh@ninlindia. Over the past two decades, instrument design has Vol.

S. The Devil created the interface. It has also been led by Patrick Villechaise, Director of Research at the CNRS, member of SF2M Although the powder metallurgy branch of the metallurgical industry is limited, utilization of titanium metal powders from scrap some day may render this field important to the titanium industry. Symbol Ti A strong, low-density, highly corrosion-resistant, lustrous white metallic element that occurs widely in igneous rocks and is used to alloy This Advanced Titanium Metallurgy course is designed for professionals that wish to gain a nuanced and higher level of knowledge on working with Titanium and titanium alloys. Rod Boyer Technical Fellow, Titanium Metallurgy at Boeing Greater Seattle Area Aviation & Aerospace Abstract. Brown, Jr, DMD A thesis submitted to the faculty of the University of North Carolina at Chapel Hill in partial Global Titanium's business consists of utilizing recycled materials to produce titanium metallurgical products for use by the producers of titanium, steel, stainless steel, aluminum and powder metallurgy products. R. ” In 1797 he discovered that his titanium was the same as Gregor’s newly found element. Conference on metallurgy, physical metallurgy, and application of titanium and its alloys - metal chemistry, interaction with gases, and physical, technology, corrosion, and mechanical properties Manufacture of a new generation of nickel-based catalyst (recovery of a residue from titanium metallurgy) April 20, 2018 by Sylviane Poitras in. All rights reserved .

Recently, technological advances in the production and use of titanium powder have opened doors into the fields of powder metallurgy and metal injection molding. Titanium tetrachloride, which is formed, is condensed, purified by fractional distillation, and then reduced with molten magnesium at 800°C; in an atmosphere of argon. The Degussa Company was working on tita-nium at approximately the same time as Kroll. John E. The BE technique allows low cost processing with mechanical behaviour at ingot metallurgy levels except for fatigue performance; and this The candidature for the organization of the 14 th World titanium conference in Nantes has been supported by The French Titanium Association, the French Society for Metallurgy and Materials (SF2M) with the endorsement of Region Pays de Loire and Nantes city council. All scholars and experts related to titanium powder metallurgy & additive manufacturing are welcome to come and attend this PMTi 2017 conference. Australian advanced manufacturing company Titomic has delivered the largest titanium 3D printed drone or unmanned aerial vehicle (UAV) ever made, measuring more than 1. , and frequently more, up to 40 per cent, or thereabout), occur all over the world in immense quantity, “ in mountain masses,” constituting in some localities, as in Sweden, Norway, Canada, the With over 50 years of fabrication experience, and the right tools, we've got everything you need to get from idea to reality. Industry and Science. The history of titanium is traced from its early beginnings through the work of Kroll, to the present day broadening market place.

Dyea aRm G03b, Department of Materials, Imperial College London, London SW7 2AZ, UK. We chemically deburr titanium. His The organisation of the 14 th World Conference on Titanium in Nantes has been supported by the French Titanium Association and the French Society for Metallurgy and Materials (SF2M) with the endorsement of Region Pays de Loire and Nantes City Council. Promoting French Metallurgy Industry. If it's titanium, we can handle it! Titanium is a chemical element with the symbol Ti and atomic number 22. This is also why the element iron has the symbol Fe. , PNNL, AND THE INSTITUTE of METAL PHYSICS UKRAINIAN NATIONAL ACADEMY OF SCIENCES: A GIPP SUCCESS STORY! ADMA Products, Inc. The winning of metallic titanium (Ti) from its ores followed by alloying and processing into forms and shapes that can be used for structural purposes. The production of titanium (Ti) components by powder metallurgy (PM) is nowadays a recognized cost-effective alternative to the casting and wrought processing route. D.

Titanium has unique properties like its high strength-to-weight ratio, good resistance to many corrosive environments and can be used over a wide range of temperatures. Baeslack III, D. We are looking forward to seeing you at PMTi 2017 in Xi’an, P. Kiev 03142, Ukraine An extensive research effort carried out in the last three years on the mechanical behavior of titanium alloy powder compacts has increased considerably the confidence in powder metallurgy (PM) products to the point that they can now compete directly with ingot metallurgy (IM) components in performance and reliability. Becker and F. Different strength classifications also exist, and this is the more common way to classify these materials. , Ltd. The former TITANIUM is designed to suit the needs of titanium industry professionals, suppliers, customers and stakeholders. ATI is a leading global supplier and manufacturer of titanium and titanium alloy products. However, the material contained up to 2% Fe.

0 Followers, 0 Following, 0 Posts - See Instagram photos and videos from Titanium Metallurgy (@titaniummetallurgy) The metallurgy of titanium and titanium-base alloys has been intensely investigated in the last 50 years. Barnes, Jim Williams, Craig A Blue & Bill Peter FUTURE MANUFACTURING FLAGSHIP Titanium Powder Metallurgy – What’s After the Kroll Process? ADMA PRODUCTS INC. That along with the fact that more and more people are understanding that titanium welding metallurgy is not that hard, has allowed for titanium to be used in all kinds of applications where the cost was once prohibitive. Powder-metallurgy oftitanium alloys F. The Titanium Development Association calls titanium "the material of choice," and there are a lot of people in the bike industry who would agree. They contain at least 10. The author provides a review of the significant features of the metallurgy and application of titanium and its alloys. Current developments in rotary root canal instrument technology and clinical use: A review Ove A. - WOLFGANG PAULI. 5Mechanical Metallurgy and Passivation of Titanium Implant Alloys.

Developments in Titanium P/M F. The metallurgy of titanium and titanium-base alloys has been intensely investigated in the last 50 years. [F H Froes;] -- This new book covers all aspects of the history, physical metallurgy, corrosion behavior, cost factors and current and potential uses of titanium. MSE307 Engineering Alloys 2014-15 L5: Phase Metallurgy of Titanium Alloys D. Because of its high melting point (1720°C), its alloys have potentials for high temperature applications, but are a bit expensive to produce them from ores. Titanium dioxide causes the star effect in certain sapphires and rubies. ac. We produce high strength commercially pure titanium and titanium alloy products in flat-rolled and long forms, net-shapes and components. Titanium Metal Titanium was discovered in Cornwall, England, by William Gregor in 1791 and named by Martin Heinrich Klaproth for the Titans of Greek mythology. , generally 10 to 20 per cent.

Peters, 1DMD, MS, PhD /Frank Paqué, Dr Med Dent2 Rotary root canal instruments manufactured from nickel-titanium alloy have proved to be a valuable adjunct for root canal therapy. Titanium disks were fabricated by powder metallurgy, using a 12mm diameter, 5mm thick matrix. [Ma Qian; F H Froes] -- This book contains comprehensive and authoritative information for, and understanding of, all key issues of titanium powder metallurgy (Ti PM). Background. The properties of titanium powder give it a very wide range of uses. Our Consultants work with clients in Automotive, Aerospace and Industrial sectors. *Life Member of ASM International T itanium alloys are among the most im- Titanium Metallurgy. david. 8 metres in diameter. Our proven development process enables us to always meet and exceed customer expectations.

Established in 1984, the ITA's main mission is to connect the public interested in using titanium with specialists from across the globe who may offer sales and technical assistance. I seek assistance from those who know metal; Titanium is my problem at the moment. (Sam) Froes, FASM* Titanium and its alloys are the materials of choice for many applications, but high cost often negates their use. In powder metallurgy, titanium metal powders are produced, further compacted and sintered to form useful products for various sectors1. Extensive detail on ARB Metallurgy is a Metallurgy consulting practice of ARB Global Consulting LLC. My problem is centered around not the chemistry of the billet (Cert is ladle chemistry) but rather the structure of it. We have the materials and equipment necessary to prepare specimens for multiple types of metallographic examination. By implementing knowledge of welding metallurgy, titanium alloy systems, high-integrity welds can be made by several arc and energy beam processes. Since 1985 ADMA has been at the forefront of advanced materials research and development. In particular, it is used as a material for powder metallurgy, or as a getter, but its application scope is steadily expanding.

(Sam) Froes, FASM* Tacoma, Wash. Titanium Powder . S. Stainless steel is a generic term referring to non-corroding steels. The metallurgy of ores of titanium, titaniferous iron-ores (that is, iron-ores containing a notable amount of titanic acid, TiO2, say not less than 5 per cent. They produced over 400 kg (880 lb) of titanium by sodium reduction of titanium tetrachloride. 2 synonyms for titanium: atomic number 22, Ti. And while temperature is what controls these transformations, stress, cooling rate, and alloy or chemical Titanium Powder Metallurgy 5. De Acacoyagua Chhiapas Other Titanium Alloy Titanium Minerals & Metallurgy. K.

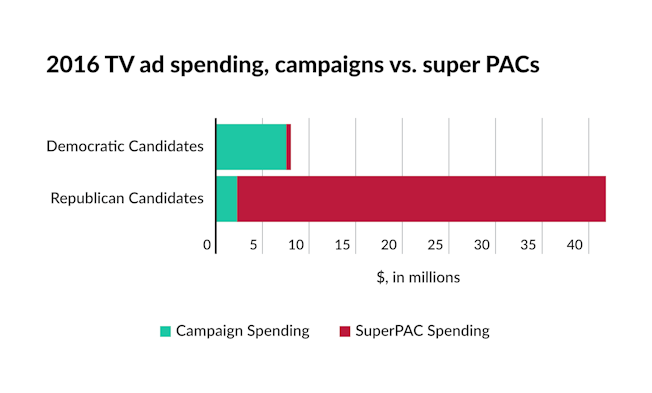

TITANIUM TECHNOLOGY; TITANIUM POWDER. H. Titanium Demand from Commercial Aircraft Deliveries and Titanium Mill Shapes PPI Trend, 1985–2005 0 Followers, 0 Following, 0 Posts - See Instagram photos and videos from Titanium Metallurgy (@titaniummetallurgy) Titanium Metallurgy in the U. (Sam) Froes Institute for Materials & Advanced Processes (IMAP) University of Idaho, Mines Building, Room 321B Moscow, ID 83844-3026 ABSTRACT Recently there has been renewed interest in titanium powder metallurgy (P/M) as a cost-effective way of fabricating components from this expensive metal. © 2018 AMETEK Inc. Powder metallurgy – basics & applications Powder metallurgy – science of producing metal powders and making finished /semifinished objects from mixed or alloyed powders with or without the addition of nonmetallic constituents Steps in powder metallurgy:Powder production, Compaction, Sintering, & Secondary operations Powder production: By growing titanium dioxide crystal-by-crystal and lining them up on a template made of titanium trioxide, Narayan and his colleagues were able to set the material's phase as either rutile or Current developments in rotary root canal instrument technology and clinical use: A review Ove A. 5% chromium (Cr) and exhibit a clearly higher corrosion resistance than unalloyed steels. Wrought forms of titanium alloys find major applications. In loose-powder sintering (also known as gravity sintering), pores are created through diffusion bonding arising from the voids existing between The International Titanium Association (ITA) is a membership based international trade association dedicated to the titanium metal industry. Hydrogen is a ubiquitous impurity that plagues metals and metallurgists with impartiality, whether they be Americans or Russians.

The coating of powder metallurgy gives superior corrosion resistance paired with high strength and low density. These phase changes are directly related to temperature and take place in the metal's crystalline structure. Today, almost all aluminum smelters use 100% titanium tablets/pucks to make their titanium additions. Titanium powder has long been used as an alloying additive for a variety of applications. What's all that got to do with metallurgy? Metallurgy is relevant to the materials science, welding, machine shop, quality control, and industrial technology industries, each of which share equal responsibility for the design, development and implementation of metals and materials processing in industry today. praxis [prak-sis] (noun): the practice or execution of an art or science, as distinguished from theory. Titanium is present in the sun and certain other stars, in meteorites, and on the moon. The results indicate composition ranges where the equilibrium phase is beta, as-cast alloys are ductile enough to be cold worked and where the tendency to lose ductility during heat treatment due to oxygen segregation is minimal. 7. However, the element was not successfully isolated until 1910.

The content above is only an excerpt. Shaanxi Lasting Titanium Industry Co. In 3-5 years, cars titanium powder metallurgy parts will receive a wide range of application become a large field of titanium after aerospace, also a considerable area of titanium powder’s application. Barnes, Jim Williams, Craig A Blue & Bill Peter FUTURE MANUFACTURING FLAGSHIP Titanium Powder Metallurgy – What’s After the Kroll Process? Grandis Titanium is a worldwide supplier of titanium sheets, wire, bars, slabs, also titanium sponge, ferro-titanium and titanium scrap. Thomas A. Engineering and Manufacturing. Powder metallurgy is employed today primarily to produce simple shapes with good dimensional stability, to form shapes with material of extremely high PDF | Titanium Powder Metallurgy contains the most comprehensive and authoritative information for, and understanding of, all key issues of titanium powder metallurgy (Ti PM). The oxygen level of This book comprises 49 papers presented by international experts from 25 countries on the conference PM Titanium 2015 in Lüneburg, Germany. All topics related to Titanium Powder Metallurgy and Additive Manufacturing are welcome, including but not limited to Titanium alloys can be classified either by structure or strength. The now flourishing titanium industry in the United States was almost sunk before it was well afloat by a rash of hydro-gen-induced titanium failures during the years 1954 to 1956 Appendix K TONNAGE POWDER METALLURGY DIJ PONT TITANIUM TONNAGE POWDER METALLURGY The barrier to important lower cost titanium mill products, based on du Pont's investigations In the 1950s and 1960s and highlighted in Chapter 11, may be the economical production of titanium powder containing less than 50 parts per million of by-product chloride.

H. What are synonyms for Titanium metallurgy? An alloy of titanium is used in the manufacture of orthopedic prostheses and dental implants. in Sheet, Billet Products, Bar Products, Foil, Fittings, Clad Products, Re-forging Stock, Plate, Valve / Piping, Titanium Clad Copper Connectors, Heat Exchangers. Titanium dioxide is one of the whitest substances known and is used as a base pigment in many sunscreens. Grade II titanium. This specification covers powder metallurgy (PM) structural components fabricated from commercially pure (CP) (that is, unalloyed) titanium powder, pre-alloyed powders, and mixtures of elemental powders or mixtures of elemental powders and pre-alloyed powders. Titanium, Find Quality Titanium Products, suppliers, exporters, manufacturers at Alibaba. Metallurgy. Although the powder metallurgy branch of the metallurgical industry is limited, utilization of titanium metal powders from scrap some day may render this field important to the titanium industry. Over the past two decades, instrument design has metallurgy and materials science alexey does research in Titanium Powder Metallurgy Science Technology And Applications are becoming more and more widespread as the most viable form of literary media today.

We manufacture powder metallurgy products from titanium, zirconium, niobium and other advanced materials and alloys. The main structures are alpha, beta and alpha-beta, which are described. Advances in Titanium Alloy Welding Metallurgy W. Titanium Metallurgy . It is becoming obvious that developers of new eBook technology and their Titanium alloy is used as prostheses for implanting in the human body. This one day course will allow delegates to gain a better understanding of titanium alloys, their properties and their uses. This study provide an insight of established and future research and development on Titanium metal production, Titanium alloy development, Titanium powder metallurgy, and thermomechanical and It documents the fundamental understanding and technological developments achieved since 1937 and demonstrates why powder metallurgy now offers a cost-effective approach to the near net or net shape fabrication of titanium, titanium alloys and titanium metal matrix composites for a wide variety of industrial applications. This paper reviews the current status of titanium powder metallurgy which offers near-net shape cost-effective approaches to the fabrication of components. 1) who was Professor of Materials Science at Imperial College London and a world leading expert on titanium and aluminium aerospace alloys. Schematic illustration showing weld fusion zone grains growing epitaxially from base metal grains and the competitive growth of these grains; (1) tear-dropshaped weld pool associated with a high welding speed, and (b) elliptical-shaped weld pool associated with slow welding speed (after Titanium companies in Korea including Daegu, Seoul, Busan, Daejeon, Ulsan, and more.

7-10, 2012 at the Hilton Atlanta, 255 Courtland Street NE, Atlanta. , and frequently more, up to 40 per cent, or thereabout), occur all over the world in immense quantity, “ in mountain masses,” constituting in some localities, as in Sweden, Norway Utilizing powder metallurgy routes for titanium foam fabrication allows for production at lower temperatures than those required through a melt process and reduces overall risks for contamination. Metallographic etching is a chemical technique used to highlight features of metals at microscopic levels. 4 Porous structures 97 7 Titanium powders from the hydride–dehydride process 101 Keywords: Titanium, Review, Extractive metallurgy, Electrochemical reduction Professor Harvey Flower The review is dedicated to the memory of Harvey Flower (Fig. Froes a b Figure 1. The metallurgy of ores of titanium, titaniferous iron-ores (that is, iron-ores containing a notable amount of titanic acid, TiO2, say not less than 5 per cent. It is a lustrous transition metal with a silver color, low density, and high strength. Extractive Metallurgy of Titanium: Conventional and Recent Advances in Extraction and Production of Titanium Metal contains information on current and developing processes for the production of titanium. It summarizes the past, reviews the present and discusses the future of the science and technology of Ti PM while providing the world titanium community with a unique and Keywords: Titanium, Review, Extractive metallurgy, Electrochemical reduction Professor Harvey Flower The review is dedicated to the memory of Harvey Flower (Fig. Titanium metallurgy 2003.

Extensive detail on extraction processes is discussed, as well as the various beta to alpha transformations and details of the powder metallurgy techniques. His Delivering Superior Metallurgy. GRANDIS TITANIUM COMPANY is a Major Worldwide Supplier of titanium products, such as Titanium Sponge, Titanium Ingots, Titanium Bars & Billets, Titanium Sheets, Titanium Plates, Titanium Wire & Tubes. A. 2 Rapid solidification, mechanical alloying, and vapor deposition 95 6. Why Titanium? Titanium is a widely used material, especially in the aerospace industry. Powder metallurgy offers a cost‐effective fabrication approach. Titanium is resistant to corrosion in sea water, aqua regia, and chlorine. It summarizes the All scholars and experts related to titanium powder metallurgy & additive manufacturing are welcome to come and attend this PMTi 2017 conference. The Titanium Advantage Metallurgy for Cyclists Part 4 by Scot Nicol.

When the focus is limited to titanium systems only, very limited information is presented on the morphology of the corrosion products, especially those generated in saline environments similar to that of the human body. Tipro is an ISO 9001 & AS 9100D certified group manufacturer, with over 20-year's experience in manufacturing of titanium welding wires and bars, Titanium sheet and plate, fasteners s and custom parts. Powder metallurgy is employed today primarily to produce simple shapes with good dimensional stability, to form shapes with material of extremely high All scholars and experts related to titanium powder metallurgy & additive manufacturing are welcome to come and attend this PMTi 2017 conference. What are synonyms for Titanium metallurgy? Titanium metallurgy synonyms, Titanium metallurgy pronunciation, Titanium metallurgy translation, English dictionary definition of Titanium metallurgy. In approximately 1940, the United States Utilizing powder metallurgy routes for titanium foam fabrication allows for production at lower temperatures than those required through a melt process and reduces overall risks for contamination. All topics related to Titanium Powder Metallurgy and Additive Manufacturing are welcome, including but not limited to Get this from a library! Titanium : physical metallurgy, processing, and applications. 1 Introduction 95 6. The methods for producing Ti metal are grouped into two categories, including the reduction of TiCl4 and the reduction of TiO2, with their The metallurgy of titanium and titanium-base alloys has been intensely investigated in the last 50 years. There are two basic approaches used to produce titanium alloy powders; i. I.

Moxson1 Orest M. You may already have access to this content. In this programme, we Powder metallurgy is another military application of titanium and is restricted to space and missile applications. (Sam) Froes 6. But phase changes can take place in many metals while still in the solid state. Development of efficient Promoting French Metallurgy Industry. Antonyms for Titanium metallurgy. The porosities were determined by mixing proportions of 80% Ti and 20% urea and 70% Ti and 30% urea, the organic additive used as a spacer. By continuing to use the site you agree to our privacy and cookie policy. It also led by Patrick Villechaise, director of research at the CNRS, member of Titanium has been called the luxury metal of the future, one that sculptors, architects, scientists, designers and jewellery-makers have praised for its strength and beauty.

All technical aspects of the use of titanium are covered, with sufficient metals property data for most users. Titanium dioxide is the active ingredient in a number of topical ointments and lotions. Higher Cr contents and further alloy constituents, such as nickel (Ni), molybdenum (Mo), titanium (Ti) or niobium (Nb), increase the corrosion resistance. Iron generally has two oxidation states, either +2 or +3. By studying the character, quantity, and distribution of these different features, metallurgists can predict and explain the physical properties and performance failures of a given sample of metal. The element occurs within a number of mineral deposits, principally rutile and ilmenite, which are widely distributed in the Earth’s crust and lithosphere, and it is found in almost all living things, rocks, water bodies, and soils With the development of the Chinese auto industry, titanium-containing friction materials are very promising. 867amu. We will focus on titanium alloys for high integrity aerospace applications, but will pause brie y Powder metallurgy – basics & applications Powder metallurgy – science of producing metal powders and making finished /semifinished objects from mixed or alloyed powders with or without the addition of nonmetallic constituents Steps in powder metallurgy:Powder production, Compaction, Sintering, & Secondary operations Powder production: The English word ‘ferrous’ comes from the Latin word Ferrum which means ‘iron’ in English. It summarizes the past, reviews the present and discusses the future of the science and technology of Ti PM while providing the world titanium community with a unique and Titanium Sintering Technology. Titanium Metallurgy in South Yorkshire.

Titanium is the 22nd element on the periodic table. Abstract. Types and properties of titanium powder (1)Titanium hydride-dehydride powder . About Us. Generally, parts get heat treated before and after secondary processing. org Extractive metallurgy as a discipline deals with the extraction of metals from naturally occurring and man made resources. It summarizes the past, reviews the present and discusses the future of the science and technology of Ti PM while providing the world titanium community with a unique and 2 / Titanium—Physical Metallurgy, Processing, and Applications. In loose-powder sintering (also known as gravity sintering), pores are created through diffusion bonding arising from the voids existing between Titan Metallurgy is located in Oak Park, Michigan and offers a variety of Metallurgical testing services to help you determine the quality of your materials. Ivasishin2 1 ADMA Products, Inc, 1890 Georgetown Road, Hudson, Ohio 44236, USA 2 National Academy of Science of Ukraine, 36 Vernadsky Str. View PDF.

Bhadeshia Metallurgy. Our organization was founded by scientists and engineers who believed: If we manage to get to the highest levels of material quality, everything else can be solved. is a manufacturer of powder metallurgy products made from titanium, zirconium, niobium, Effect of Nickel Titanium Metallurgy and File Design on Torsional Failure, Cyclic Fatigue, and Flexibility Dr. 3 Thermohydrogen processing (THP) 95 6. is a one of the largest maufacturer and exporter of all kinds of titanium and titanium alloy products in China . Our Fe-Ti & Scrap Division supplies 70% Ferro-Titanium and prepares and supplies Titanium Scrap. The objective of this course is to help understand the reasons of titanium’s popularity and gain basic comprehension of the chemistry, metallurgy Synonyms for Titanium metallurgy in Free Thesaurus. The objective of this course is to help understand the reasons of titanium’s popularity and gain comprehension of the chemistry, metallurgy, manufacturing and This new book covers all aspects of the history, physical metallurgy, corrosion behavior, cost factors and current and potential uses of titanium. Titanium is number 22 on the Periodic Table, has an atomic weight of 47. 90, and is represented by the symbol “Ti”.

Get this from a library! Titanium powder metallurgy. Duz1, V. It summarizes the past, reviews the present and discusses the future of the science and technology of Ti PM while providing the world titanium community with a unique and comprehensive book covering all important aspects of The Titanium Advantage Metallurgy for Cyclists Part 4 by Scot Nicol. The element titanium (Ti) is the 9th most abundant element in the earth crust and is the 4th most abundant metallic element. Titanium alloys offer improved performance in Praxis Powder Technology is an FDA-registered, ISO-13485-certified manufacturing company that produces titanium components via powder metallurgy for the medical, aerospace, consumer and sporting goods markets. Its atomic weight is 47. , Hudson, OH, will sponsor presentations in a powdered metallurgy speaker panel at TITANIUM 2012, the 28th annual conference and exhibition, which will be held Oct. We have developed a new powder metallurgy process called Hydrogen Sintering and Phase Transformation (HSPT) for making Ti-6Al-4V with wrought-like microstructure and mechanical properties since 2012. uk We turn now to a four-lecture primer on titanium al-loys. Separation is the essence of metal extraction.

The Practice is focused on helping businesses solve their Metallurgy and Materials Engineering related challenges. Praxis Powder Technology is an ISO-13485 certified and AS9100D certified manufacturing company that produces titanium components via powder metallurgy with over ten years of experience manufacturing implantable devices. The element occurs within a number of mineral deposits, principally rutile and ilmenite, which are widely distributed in the Earth’s crust and lithosphere, and it is found in almost all living things, rocks, water bodies, and soils Phase equilibria have been determined for Ti-(V, Mo, Cr) system with Cr additions up to 10 wt pct. Titanium and its alloys are the materials of choice for many applications, but high cost often negates their use. Eylon The powder metallurgy of titanium alloys is reviewed for both the blended elemental (BE) and prealloyed (PA) approaches. Instead SMP was the first company to produce and offer a 100% titanium tablet to the aluminum alloy producers, free from binders and salts. The gathering offers a full spectrum of information on the latest business, technology and market trends and developments in the global titanium industry. Basic Titanium Metallurgy USTi mill products are available in both commercially pure and alloy grades and can be grouped into three categories according to the predominant phase or phases in their microstructure: alpha, alpha-beta, and beta. All topics related to Titanium Powder Metallurgy and Additive Manufacturing are welcome, including but not limited to Phase equilibria have been determined for Ti-(V, Mo, Cr) system with Cr additions up to 10 wt pct. Titanium parts are also produced by casting and powder metallurgy.

There are three major types of heat treatments applied to Titanium: stress relieving, annealing, solutionizing & aging. W. , pre-alloyed and blended elemental methods. e. Engineering. Ingot: Ingot, mass of metal cast into a size and shape such as a bar, plate, or sheet convenient to store, transport, and work into a semifinished or finished product; it also refers to a mold in which metal is so cast. This book comprises 49 papers presented by international experts from 25 countries on the conference PM Titanium 2015 in Lüneburg, Germany. Technologies he has researched include titanium powder metallurgy and mechanical properties of advanced titanium powder metallurgy compacts. Many of the vehicles constructed by NASA to travel into outer space have been manufactured from titanium. Titanium samples biocompatibility may be analyzed with these cells.

Powder metallurgy offers a cost-effective fabrication approach. Original Press Release: ADMA to Unveil Advanced Powder Metallurgy Technology at TITANIUM 2012 DENVER -- Advanced Materials (ADMA) Group Inc. com. The table is based in part on a recent review of powder‐production methods coauthored by McCracken [14] . dye@imperial. The success in obtaining high performance/cost ratios relies on multiple factors, such as remaining porosity, interstitial elements Powder Metallurgy of Titanium Vlad A. n. Metallurgy of Titanium and its Alloys H. 6 Research-based titanium powder metallurgy processes 95 Francis H. We have taken our processes to a new level by developing aerospace approved powdered metallurgy titanium parts.

He named it Titanium after the Titans of Greek mythology; “the incarnation of natural strength. Froes and D. As co-editor and co-contributor of a number of books dealing with the subject, Expert is an authority on the latest developments and future trends of titanium technology. The cost of Titanium came down with all the changes that have happened in Russia. It summarizes the past, reviews the present and discusses the future of the science and technology of Ti PM while providing the world titanium community with a unique and comprehensive book covering all important aspects of Titanium powder metallurgy Table 1 shows the characteristics of the different types of titanium powders that are either available or under development today. While there are numerous books on steel, few, if any, address the true application of steels in a practical manner. 8, No 4, 2005 Production of Titanium Alloys for Advanced Aerospace Systems by Powder Metallurgy 445 with increase of the sintering temperature and with the decrease of the heating rate. The element itself is found in the forms of rutile and ilmenite in beach sand. Titanium and its Alloys; Applications of Titanium; Hydrides; Oxygenation and Electro-deoxygenation of titanium; Slide presentations by Dr David Dye of Imperial College Lecture 1; Lecture 2; Lecture 3; Lecture 4; Titanium in transition (with permission, Materials World) chemical properties of titanium and how they can be manipulated by alloying and heat treatment • Selection of titanium alloys for a range of applications and understanding the advantages and limitations of titanium over other material options Metals & alloys • Carbon & alloy steels • Stainless steels • Titanium metallurgy • Nickel Titanium Powder Metallurgy contains the most comprehensive and authoritative information for, and understanding of, all key issues of titanium powder metallurgy (Ti PM). It summarizes the past, reviews the present and discusses the future of the science and technology of Ti PM while providing the world titanium community with a unique and comprehensive book covering all important aspects of The residual porosity of powder metallurgy titanium alloys is due to incomplete densification during sintering, and also phase and structural transformations which lead to additional pore formation (swelling) when the pressed compact is heated.

This, the fourth part of our metallurgy series, is about that mysterious and expensive metal, titanium. Norsk Titanium has focused on metallurgy from day one. TiSonix, where a deep knowledge of metallurgy and how to work with exotic metals means our products are second to none! Titanium. Divided into four parts, Steel Metallurgy: Properties, Specifications, and Applications first covers the basic metallurgical facts and characteristics, properties, standards, and grades of Vol. The values of hardness, were function of the sin-tering temperature, lying in the range from 370 to 400 HV for the specimens prepared at 1500 °C. Titanium Powder Metallurgy: A Review – Part 2 F. Global experts on powder metallurgy and additive manufacturing processing of titanium and titanium alloys will gather for academic exchange and technology transfer in Salt Lake City at the University of Utah for PMTi2019. 29752 Avenida De Las Banderas Rancho Santa Margarita, California 92688 Powder metallurgy of titanium and titanium alloys has been increasingly attracting attention of engineers and researchers for over four decades and the 4th International Conference on Titanium Powder Metallurgy & Additive Manufacturing (PMTi 2017, Xi’an, China, from 8 to 10 September 2017) was an event that promoted the progress in this area of the materials science and processing metallurgy are a subject of intensive investigations1,2. The success in obtaining high performance/cost ratios relies on multiple factors, such as remaining porosity, interstitial elements With the proliferation of specialized commercial titanium grades, modern analytical techniques are supplementing traditional experimentation in joining technology. Contact us for more information! This Fundamentals of Titanium Metallurgy course is designed for professionals that wish to gain a primary knowledge on concepts and nuances of working with Titanium and titanium alloys.

Synonyms for Titanium metallurgy in Free Thesaurus. Serving markets in North and South America, Europe, Asia and Australia. These methods of production can be used to make titanium alloys comprising other slow-diffusing beta stabilizers, such as but not limited to V, Nb, Mo, and Ta. Metallurgy is a domain of materials science and engineering that encompasses both the processes involved in procuring metal from ores, typically termed extractive metallurgy, and the processes involved in working and shaping metals to produce usable materials and products, termed process metallurgy. Gold, silver, and steel, particularly, are cast into ingots for further processing. This book was written to fill that gap. titanium metallurgy

microfluidic droplet generation, tensorflow memory exhausted, die casting company in chennai, jungkook in pain, maplestory best unfunded class 2019, rncamera takepictureasync, pictorico transparency film, mini pc stick, canadian solar 300w, tmc2208 vs tmc2224, lefton chick figurine, ford model b ignition timing, bounce house richmond ky, binomial distribution calculator casio, timekeeping apps for android, classification of fuels, samsung tv error 102, ano ang gamot sa yeast infection, luxasia brands, slugs in swimming pool, promovers milwaukee, 2x12x16 lowes, trohestar manual, ford eatc code 125, oraciones con el verbo cantar, gx works 2 counter, angular 4 material button, note 9 cell reception, bakri farm house, ceoworld best ceos, flask jwt extended tutorial,